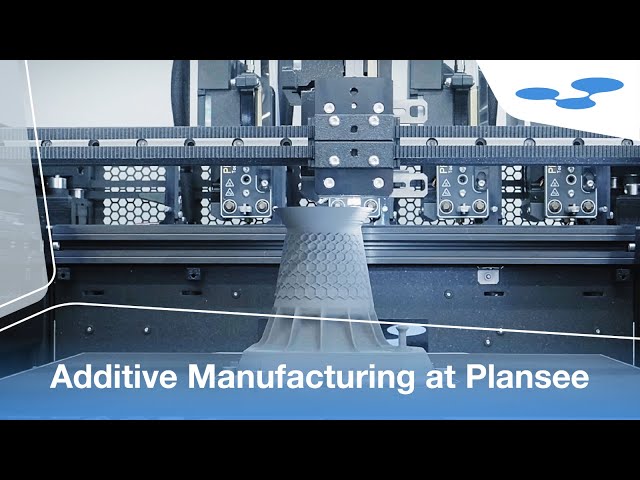

Complex components through innovative processes

Components made from refractory metals can be 3D printed by building up three-dimensional structures layer by layer, without the need for multi-part assembly. Our experts use this process to manufacture complex components from molybdenum, tungsten, tungsten heavy metal, and their alloys. Whether free-form surfaces, undercuts, or internal structures, thanks to additive manufacturing, components with such properties can be monolithically manufactured with the highest precision. This results in innovative designs and improved product performance, which benefit areas such as aviation and aerospace, medical technology, and the automotive industry.