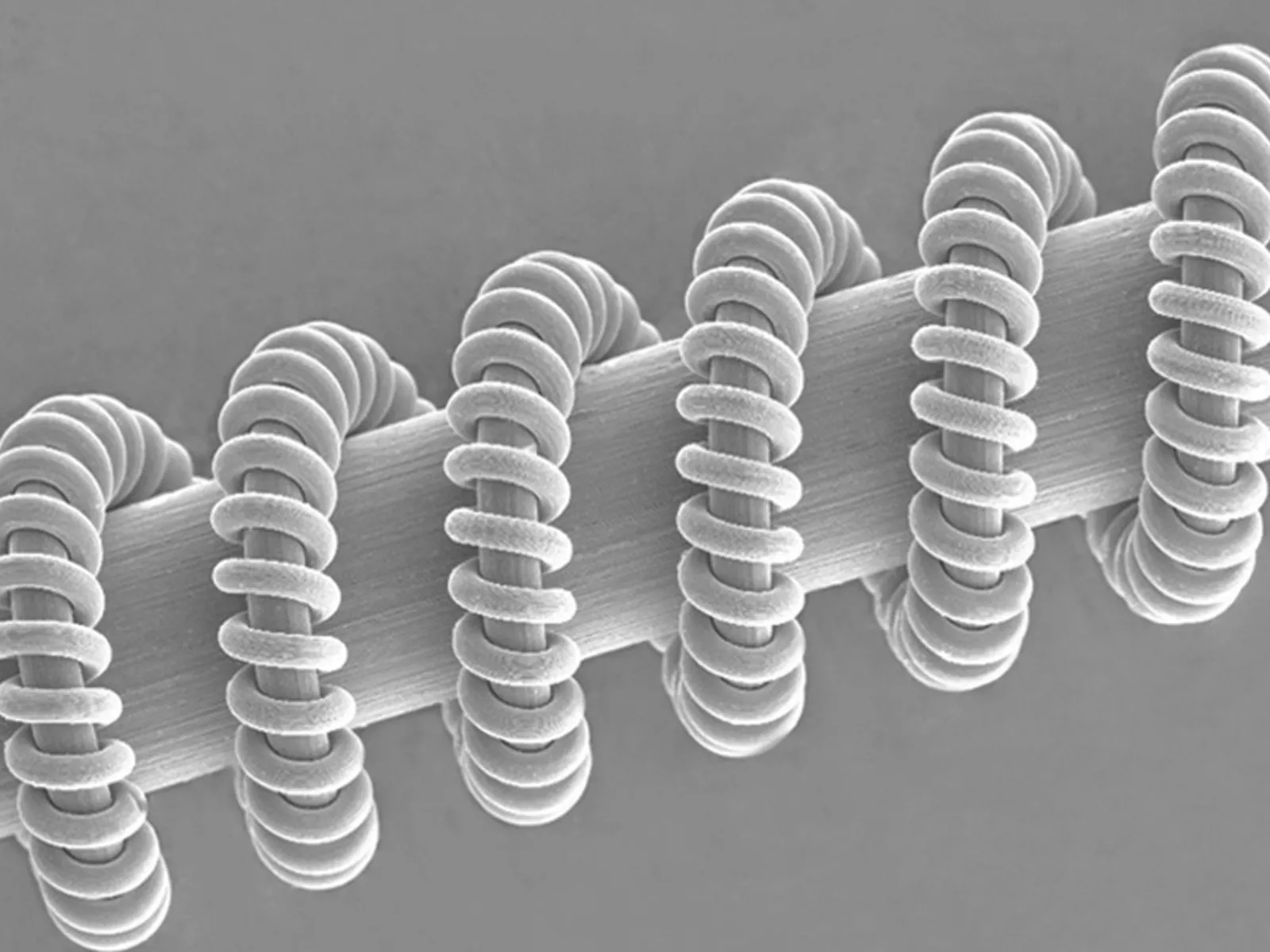

When producing the Mo-ILQ wire, 300 µg/g lanthanum oxide is added to pure molybdenum. This increases the recrystallization temperature of the core wire. The homogeneous, elongated microstructure ensures that our Mo-ILQ core wires remain ductile, even in a recrystallized state. Our Mo-ILQ wire is considerably more ductile than pure molybdenum wire, even after the annealing stage of the filament manufacturing process.