Our medical fine wires were designed for use under the most demanding conditions. We provide you with the suitable surface quality.

The most important properties of our standard products at a glance:

Fine wires made of tungsten and potassium-doped tungsten are well suited for medical wires for components used for brain stimulation and neuronal studies. With minimum diameters of up to 0.010 mm, these ultra-fine wires are used in surgical robots, stents, guide wires for catheter operations as well as in electro-surgeries. The high density of tungsten gives our medical wires their unique radiopaque visibility.

Our fine wire is well tolerated by the human body and impresses with its freedom from fissures, very high surface quality, very low diametrical tolerance as well as stable mechanical properties. We subject this wire to a comprehensive quality control system during manufacturing. In this way, we can ensure our customers consistent high product quality while meeting the strictest quality standards.

Decades of experience in medical technology

High material purity

> 99.5%

Available with a minimal diameter of 0.010 mm

Thorough quality control in our own lab

Guarantee of fissure-free surface

Development partnerships

Our medical fine wires were designed for use under the most demanding conditions. We provide you with the suitable surface quality.

The most important properties of our standard products at a glance:

| Material | Purity | Diameter | UTS (MPa) | Expansion | Surface treatment |

| W | > 99.97% W | 18 - 30 µm | > 3,400 | > 1.8 | Electropolished |

| WK65 | 99.5% W 60 - 65 ppm K |

18 - 30 µm | > 3,000 | > 1.5 | Electropolished |

| WL10 | 99% W 1% La |

18 - 30 µm | > 4,000 | > 1.0 | Electropolished |

The unique properties of our ultra fine tungsten wire enable us to offer you a precision wire of the highest quality. And when we say "fine" we mean a minimum diameter of up to 0.010 mm. In comparison: human hair has an average diameter of 0.075 mm, making it almost eight times as thick.

We guarantee:

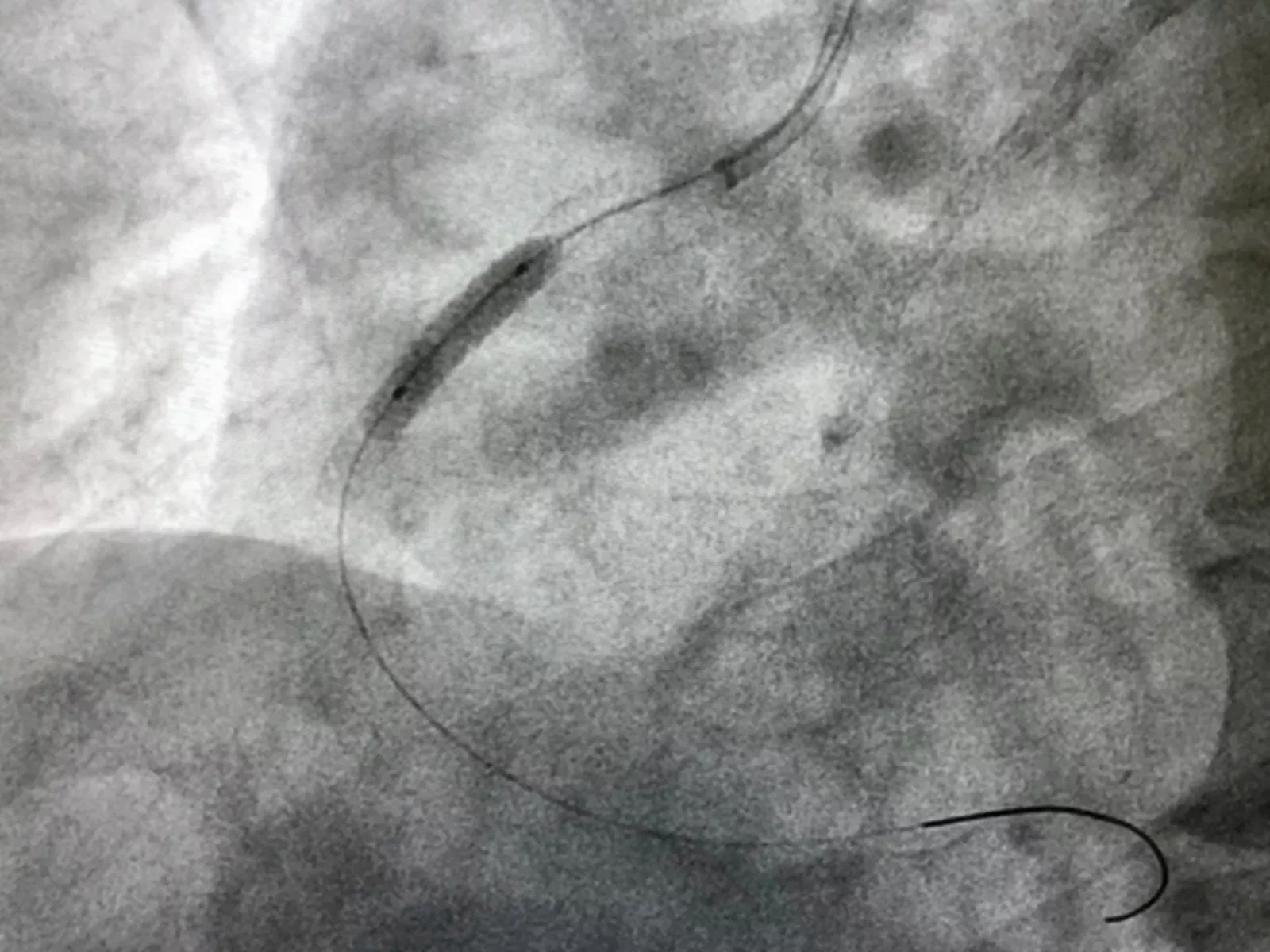

A guide wire ensures safe and precise access to blood vessels and organs. Thanks to its high density, the fine tungsten wire is very easy to see on the x-ray image during the procedure. Guide wires made of tungsten are also used for inserting and positioning catheters for blocked heart valves or channels.

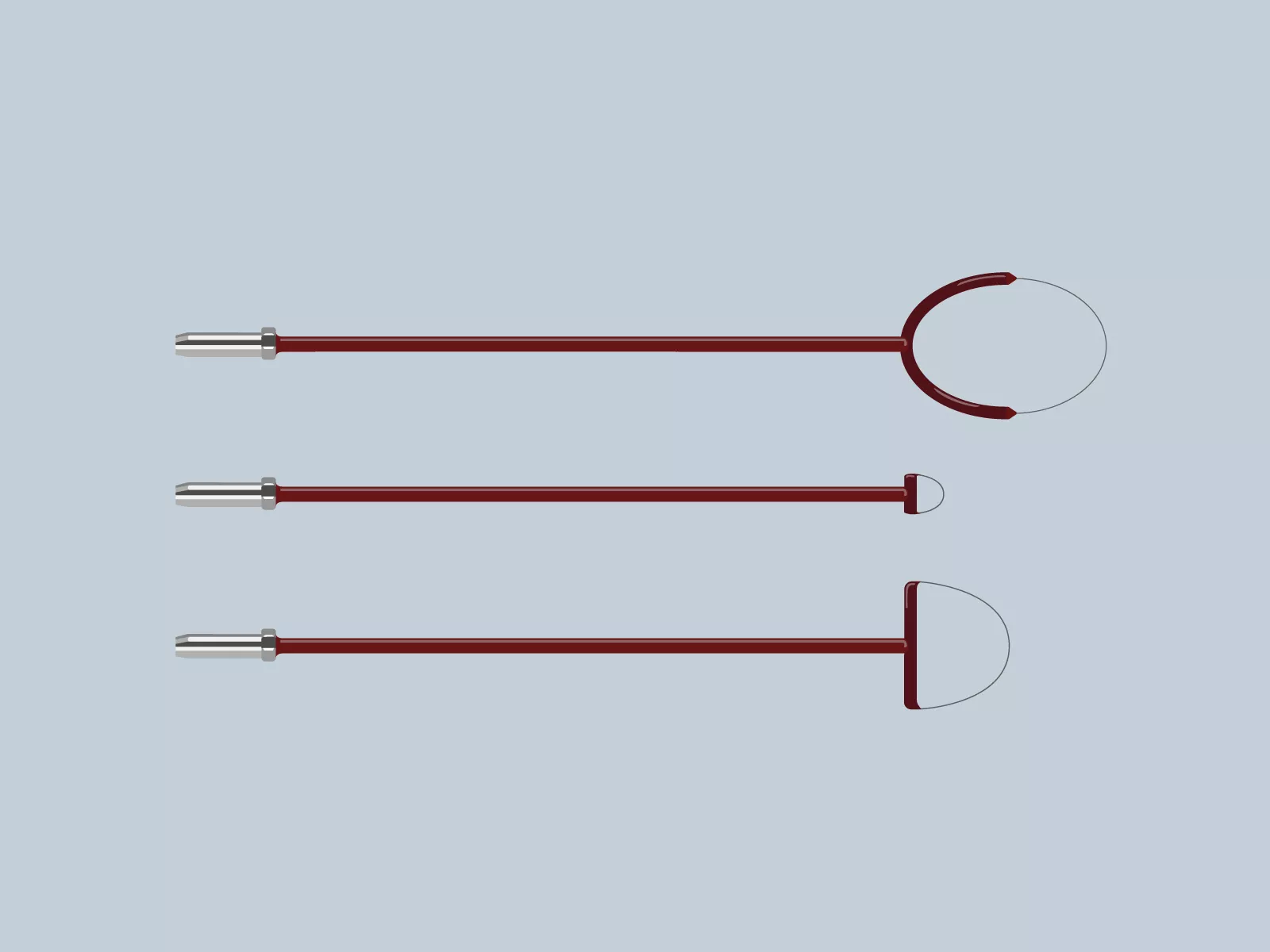

During electro-surgery, alternating current is channeled at high frequency through the human body. Electro-surgical electrodes such as tungsten needle and wire loop electrodes offer improved performance for cutting and coagulation. Therefore, they offer surgeons the required precision for numerous procedures.

Surgical robots are very important for intelligent surgery. These smart systems and instruments offer precision, flexibility, and control for many types of procedures. We manufacture fine tungsten wires for these robots using the highest machining accuracy and broadest technical know-how.

We know the requirements for the products being used here very well due to our decades of experience in the area of medical technology. Our material scientists and engineers will work together with you on finding innovative and individual solutions for your application, from prototypes to small series and large-scale production. In addition, we also help to ensure ideal process development and guarantee our customers impeccable material testing and analysis.

Uncompromising quality and the highest degree of accuracy are the prerequisites for medical technology. That's why we do not outsource here. Our production chain starts with the reduction of ultrapure oxide to metal powder. This is the only way that we can guarantee the high material purity of our products. You benefit from our in-house production as well as our international manufacturing network, meaning delivery capability is guaranteed.

Other products for medical technology: