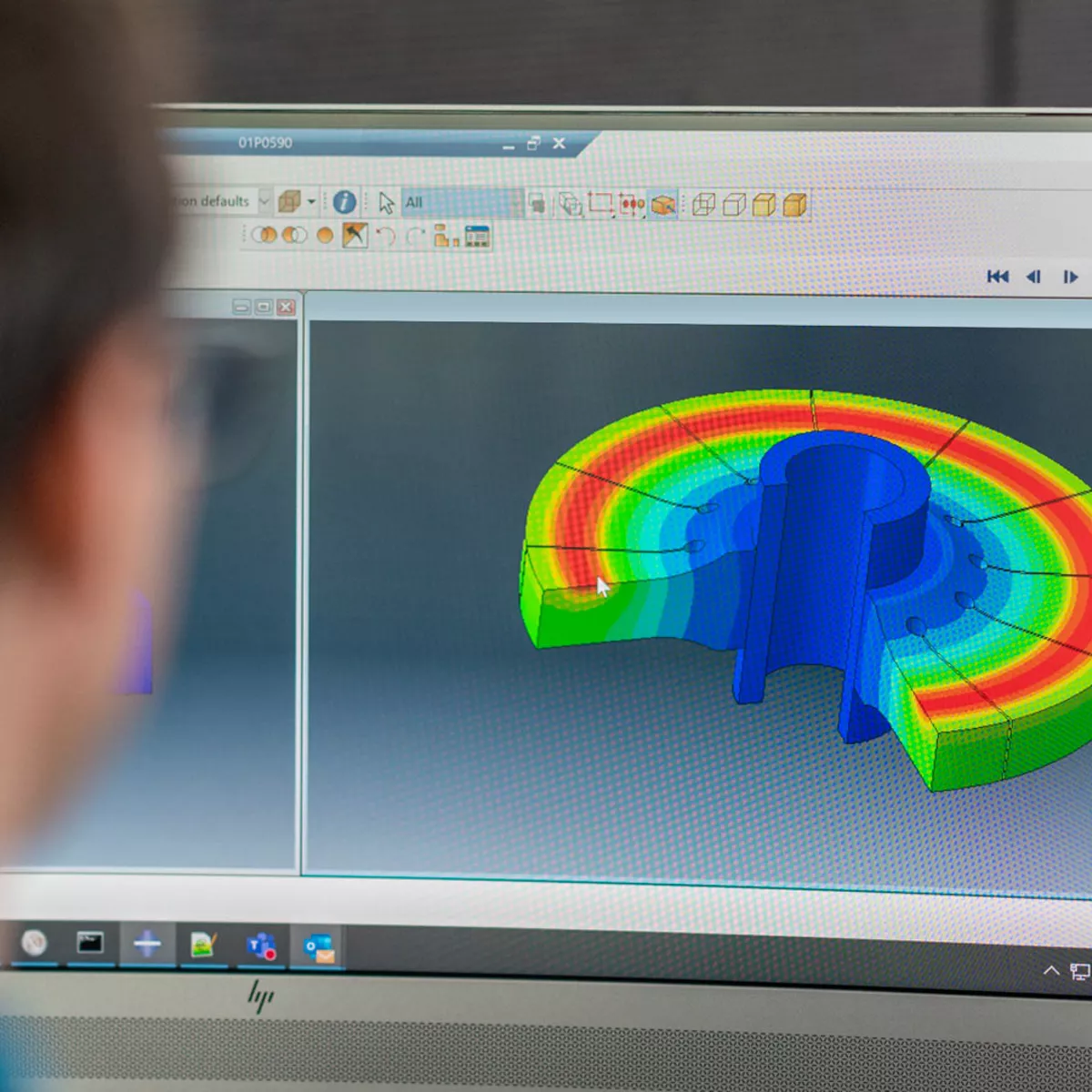

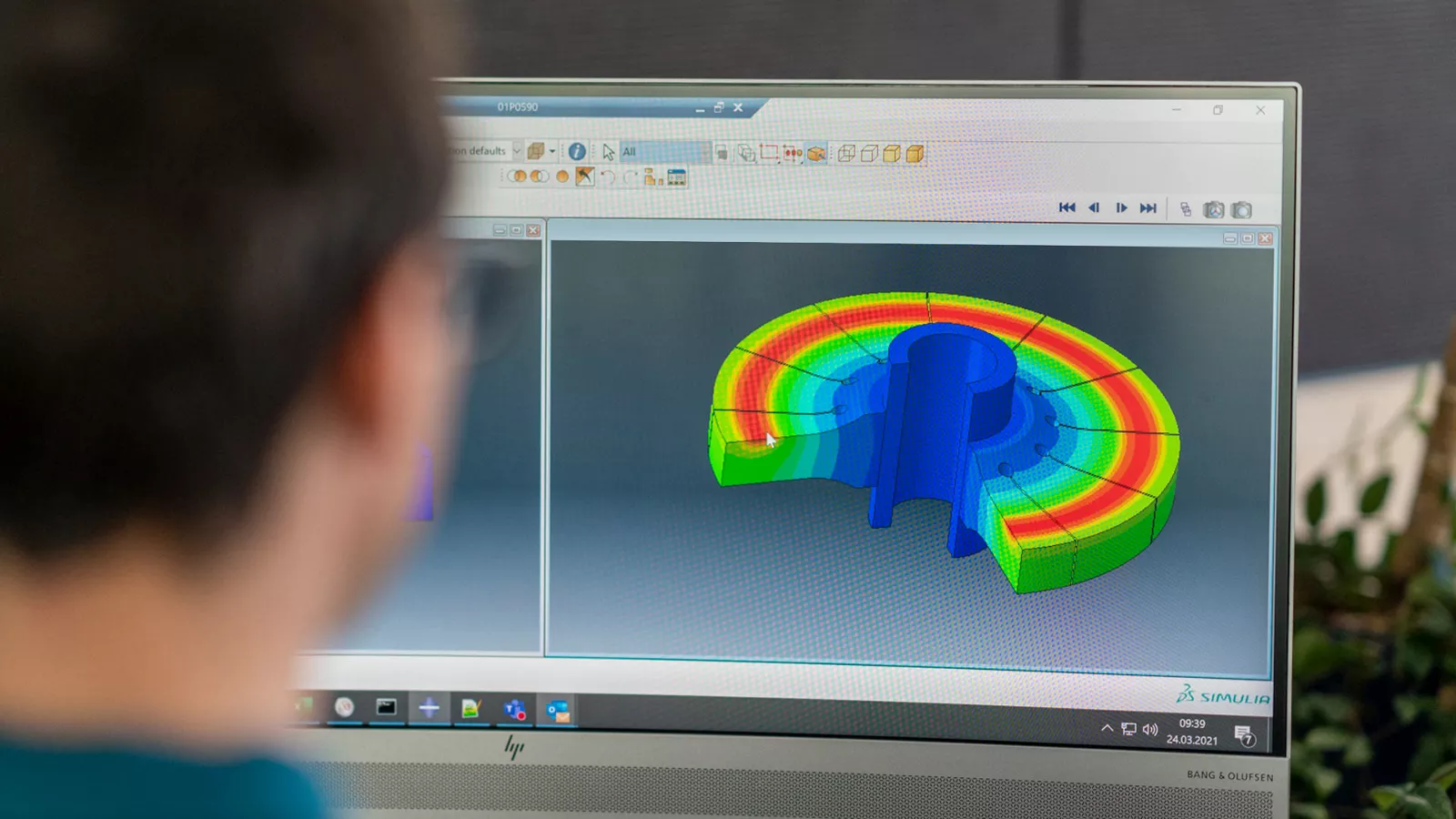

Our experts will work very closely with you to determine the right material selection and manufacturing option for your needs. Our engineers and designers will support you in the creation of product specifications. We use only the latest engineering tools in the design process:

Our expertise in manufacturing and technology

We are passionate about molybdenum, tungsten, tantalum and tungsten-based composites. We have been continually expanding and enhancing our skill set in the area of manufacturing and technology since 1921. That's why today we have experts covering the entire range: from powder to the final product. We offer fast and flexible implementation from product design, distribution and manufacturing to supply chain solutions by making use of our in-house expertise. This enables us to meet your exact requirements and produce tailor-made products of the highest quality: from prototyping to single item, series and large-scale production.

100 years of powder metallurgy expertise

Proximity to customers through 5 locations with engineering expertise

Largest rolling mill for refractory metals: 15 μm and 50 mm

Assembly on 255 m2 of ISO 6 clean room space

Product management: from idea to implementation

Our areas of expertise at a glance:

- Computer-aided design (CAD)

- Computer-aided manufacturing (CAM)

- Coordinate measuring machine (CMM)

- Special test and analysis processes for component optimization

- Modeling of components using the finite element method (FEM)

- Simulation of usage conditions using computational fluid dynamics (CFD)

- Prototyping with initial sample analysis and documentation

We have all key competencies and technologies at our disposal when it comes to the manufacturing, processing and refining of our materials. We customize the property profiles of our materials to your individual requirements specification. Starting with the reduction of ultrapure molybdenum and tungsten oxide to pure metal powder: powder metallurgy allows us to produce materials with melting points of well over 2000 °C. The procedure is particularly economical even when only small quantities are produced. Tailor-made powder mixes enable a wide range of extremely homogeneous materials endowed with specific properties to be created. This process takes place in our production sites.

From powder to the end product

Our in-house production chain starts with the reduction of ultrapure oxide to metal powder. This is the only way to achieve the high material purity of our products. We guarantee optimally balanced material properties and a particularly homogeneous material composition through our powder metallurgy production process. We manufacture compact, metal parts from porous powder blanks. Using special forming processes and mechanical processing steps as well as modern coating and connection technologies, we turn these into complex components with a maximum density and the highest quality. At the same time, our investment in mines in the West helps to ensure a secure supply of raw materials. You also benefit from our in-house production as well as our international manufacturing network, meaning delivery capability is guaranteed.

The powder metallurgy production of refractory metals is currently a recognized green technology due to its material usage, energy consumption, and emissions.

Plansee is a member of the European Powder Metallurgy Association (EPMA).

The special properties of our materials, such as their high-temperature stability and hardness, place particular demands on forming technology. Our decades of experience, however, has enabled us to form sinter blocks via forging, rolling and drawing with ease. Plansee components are frequently used at very high temperatures. Lots of experience and care is required to ensure the high mechanical strength of our materials after forming. We precisely regulate the temperatures during forming and take the time for several additional processing steps such as intermediate annealing.

- Plansee can forge rods on modern radial forging machines precisely to the various final diameters and with very strict tolerances. The benefit for you is that the forged surface and the microstructure guarantee optimal mechanical properties throughout the entire cross section of the rod.

- We produce thin rods and precursor material for wires using continual rolling processes. This so-called caliber roll ensures optimal properties for further processing.

- We draw out course and fine wire from the rolled precursor material. We precisely control the temperature and form wires that are especially smooth and uniform using diamond and hard metal tools on modern drawing machines.

- We produce sheets with thicknesses between 15 μm and 50 mm on various rolling machines. We work with the world's largest hot-rolling mill for refractory metals, among other things. It has a rolling force of 50,000 kN (kilonewton).

- We produce tubes with a high density and a homogeneous microstructure via forging and drawing.

We adapt the chipless and chipping machining methods used to the special material properties of our materials to ensure the mechanical processing of our high-precision components. This now enables us to produce components in all dimensions: our smallest product currently weighs just two grams, while the largest approx. five tons. Plansee uses its own production network of approx. 3000 different processing machines for the following applications:

|

|

High-temperature materials require special joining technologies. With our decades of development and experience, we have turned joining technology into a key area of expertise.

We solder a variety of components to meet functional requirements with modern solderers. We can achieve firmly bonded material combinations for materials of both the same and different types (refractory metals, steels, copper alloys, graphite or ceramic). We use different solder alloys depending on the specific applications:

- Soft-soldering < 450 °C In, Sn – base solders Hard-soldering

- < 900 °C Al, Ag, Cu – base solders

- High-temperature soldering > 900 °C Au, Pd, Ni, Zr, Ti – base solders

|

|

Chemical, electroplated, thermal and PVD coatings are applied in our own facilities. Along with professional cleaning, degreasing, pickling and electro-polishing, we also equip your product with the desired coating, from gold, silver and nickel to ruthenium, chromium, aluminum and many more. Our core expertise in this area includes:

|

|

|

The highest precision is provided when it comes to the assembly of highly complex components and modules. This is because quality is our number one priority. In many industries, maximum cleanliness is also required, for example the semiconductor and medical technology industries. Maximum cleanliness. At Plansee, we have a 255 m² ISO 6 class clean room. We also have a 70 m² ISO class 8 clean room. There we assemble not only our own components, but also purchased parts that we procure from qualified sub-contractors. Our purchasing and inventory management processes ensure a seamless supply of supplier components. We equip assemblies for the semiconductor industry – which are required for the production of the latest computer chips – with heating conductors, thermal sensors, ceramic elements as well as insulators.

Before any components make their way into the clean room, they first undergo a thorough cleaning. We clean the components in either aqueous or spirituous ultrasound cleaning units depending on the material. In order to achieve the Grade 2 Standard, refractory metals can only be annealed at 700 °C when all surface oxides and other organic impurities have been removed. Finally, a UV black light inspection is then used to check whether all components are actually free of impurities such as fingerprints or particles.

In addition, we also have our own bakeout and residue gas analysis systems (RGA). If required, we can heat components to 120 °C and then determined the outgassing. We can perform these residue gas analyses ourselves for even very large assemblies. If only a few small parts need to be qualified, then we rely on our network of external partners.

Assembly in the clean room at Plansee